Constructions

Things I have built throughout the years

K'nex gun (2007)

A small single-shot rubber band "gun" with trigger handle. It could shoot those grey rods very far very fast. That's all I remember. Maybe it's time for a remake.

Trebuchet (2007)

This one I built with two friends and my dad when I was fourteen. I probably became inspired after playing the game "Medieval II: Total War". The counterweight consisted of a tank filled with water and the projectiles we used were plastic "lawn bowling" balls, which were thrown ca. 50m far. With this trebuchet, I learned the angle and length of the metal release pin at the end of the arm are important for the right timing of the throw.

Back in 2007, I could not make a video sharp enough to show the projectile fly. However, interesting is the slow-motion shot at the end of the video.

PVC-Crossbow (2008)

When you have some basic materials you can already make a big crossbow. Maybe it's even easier to make than a small crossbow. Anyway, in the photos you see an example crossbow I saw in France on holiday. My downgraded version consisted of a PVC-tube with clamps and a plank. Did it work? Not really, there were two problems. Firstly, there was no good trigger system. The bowstring would not always push the arrow. Secondly, the lack of a barrel made aiming impossible. Credits to dad for welding the (disfunctional) release trigger design.

Water rocket triggered launch pad (2008)

We all know the water rocket we built as a kid: fill a soda bottle with one-third of water, put a cork in the throat with a bicycle air valve, and watch it fly when you build up pressure. A friend of me found a design online that improves this basic toy. With a PVC ring, rubber O-ring seal and tie-wraps, we made a mechanism to hold down the bottle. When the ring is pulled down with a rope, the tie-wraps bend away and the bottle is free to go up. I could not find more footage of this launch pad, but I remember well that we could pressurize the bottle with a compressor and trigger when the bottle looked as if it could explode. A problem was that the O-ring seal was leaking when the pressure built up, so we lost some water during pressurization. I have no idea what happened with this thing, but one day I will make a better version.

Mini ballista (2008)

For this one I have to give credits to my primary school friend Jorrit and his dad. I explained him what I knew about ballistas from the Rome Total War PC game, and I brought a plastic scale model to show. I remember he then did most of the building of this construction. As shown, this hand-held ballista could pierce wood with sharpened rods. We were amazed by what we created and it made me think about a bigger version.

Big Ballista 1 (2008)

With scrap wood from a neighbour, some metal tubes and a box of screws I built this machine with my friend Arno. This ballista was very heavy, had no standard for mounting it and used wooden arms that were too heavy. If you read about the PVC-crossbow you recognize the disfunctional trigger system. And yet it worked well sometimes. Unfortunately, because there was no winding mechanism, the ballista could not be tightened beyond human power. It took a while to tension the springs with a long metal rod. If it worked, we could shoot potatoes, tomatoes, metal tubes and other stuff. There is better documentation of Big Ballista 2

Big Ballista 2 (2012)

Our baby: the "new" ballista was built four years after the first one. We think it was very deadly, but we did only check that with our thick cardboard barbarian "Oggel" (check the video). This time, my friend Arno and I were doing engineering studies, so we learned to make better plans before we dived into building.

This ballista had a metal rachet to pull back the entire barrel and bowstring. The barrel would slide over a wooden plank with edges on the side, so the energy stored in the springs depends on how far the barrel is pulled back. The trigger consisted of a sort of lever hook that hinged on a bolt. It was held down by a metal piece clamped between back of the hook lever and the barrel. When this block was pulled out, the hook would be pulled open and a small wooden block on the bowstring would push the projectile forward through the barrel. When you do the math, you find that you want short arms on the ballista to save energy. That's why they are relatively far apart. Tensioning the ropes symmetrically proved to be difficult. Also, the metal block holding down the trigger would sometimes get stuck. Those were scary moments, as we had no system to safely remove the energy and cancel a shot.

As you see, we could shoot arrows and metal bars to blow away our target.

Typing robot (2016)

In case you wonder why there is a four-year gap between the previous construction and this one on this page, it is because I dedicated a separate page to the hydrofoil engineering for TU Delft Solar Boat 2013/2014.

Anyway, on the left you see a typing robot arm I made with a friend for the Msc. course of Spacecraft Mechatronics. The arm was designed by my friend Dimitrije, while I programmed the Arduino. The robot looks smarter than it is, because there is no feedback loop involved: every key on the keyboard was carefully calibrated, so with a different keyboard or a slight change in positioning it would output nonsense.

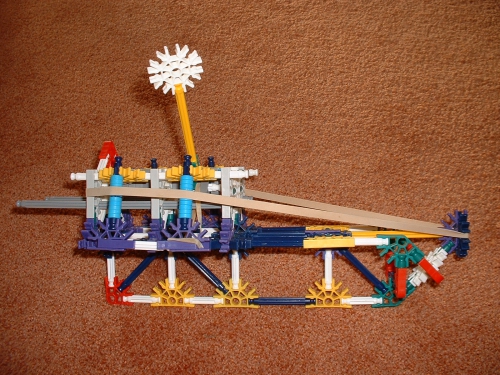

K'nex tower crane (2017)

Just a holiday project. The 2.5m crane is supported by 16 small wheels to make it rotate. A piece of K'nex rollercoaster track was used for the carriage and lifting platform. Dry pasta is used as the counterweight, why not.

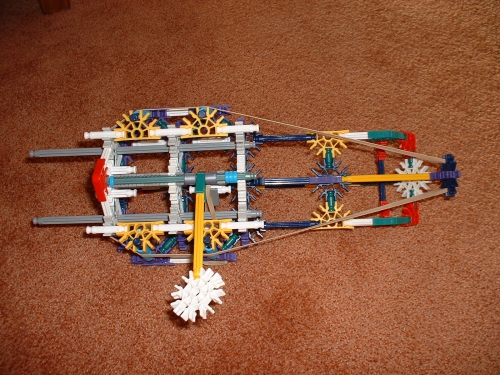

Cable-stayed K'nex bridge (2019)

The only way to have your girlfriend allow such hobbies, is when you promise to build a bridge specifically to bring chocolate from the kitchen to the sofa. So that's what I did. The rail and carriage system could be moved with pulleys to drive the carriage back and forth with home cinema food supplies. Nevertheless, I had to take the bridge down after I was forced to admit it was very inconvenient in practice.

K'nex working pendulum clock (2020)

Our kitchen clock broke down, so I planned to make one from a piece of tree trunk and a normal battery powered clockwork. I did not know where to start, so as a temporary solution I started working on a pendulum clock from K'nex.

I did not know how pendulum clocks worked, but with the wikipedia page about anchor escapements I was able to get it to work. Soon, I would fill my evenings with improving it. After a month or so, this was the result. It worked for twelve hours on a single rewind and was accurate enough for practical daily use, thanks to the minute and hour hands. I can write a whole story here, but you can just watch the 6-minute video that explains it all.

Is it still in use? No, because at some point I could not improve it anymore. Everything I tried made the performance worse and at some point I gave up and broke it down to protect myself from more frustration. But I am sure a better version will one day follow in his footsteps.

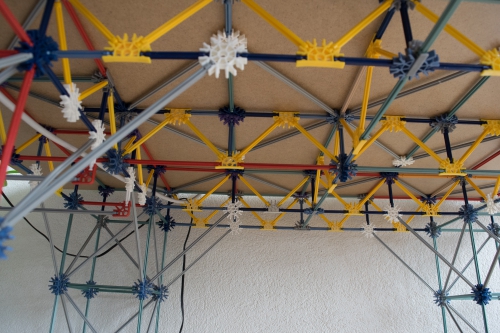

K'nex covid home office desk (2020)

Extremely functional, modular and lightweight! We had to work from home during the corona virus pandemic, and we only had one desk at home for the two of us. This project started as a sort of joking attempt to create more office space.

Surprisingly, the K'nex desk really worked well. It could easily hold the monitor, laptop and cups of coffee. With some care, you could even lean on it. My girlfriend used it daily for a few months. The desktop consisted of three thin MDF sheets. Regular maintenance was needed though, as connections could get loose without notice. Still, a highly recommended design!